Manual Back-Stitch

Sometimes back stitching is not a good option for different and often frustrating reasons, such as a thick, bulky seam and/or the seam is just not staying flat, the needle gets bent and breaks, the thread is looping up…

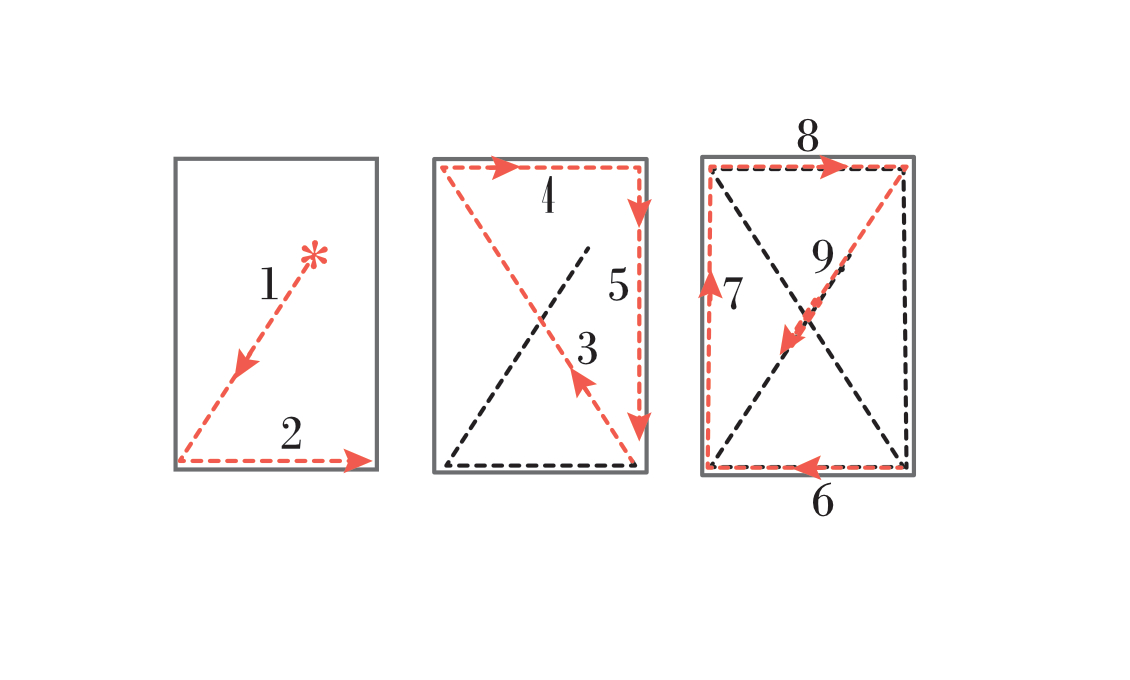

This trick shows you how to back stitch manually by always sewing 'forward' and turning the fabric instead.

Step 1

Start sewing about 3 - 4 cm (1.2 - 1.6") away from the difficult part.

Sew about 1 - 2 cm (0.4 - 0.8"). Do not back stitch.

Step 2

Leave the needle in the material, lift the presser foot, and turn the material 180 degrees. Sew over the first stitches all the way to the difficult part.

Step 3

Leave the needle in the material, lift the presser foot, and turn the material 180 degrees again.

Tip:

Sometimes it helps to place a pin right into the corner. Use the pin to hold and guide the fabric in place.